Module encapsulation and interconnection of IBC-SHJ devices (WP7)

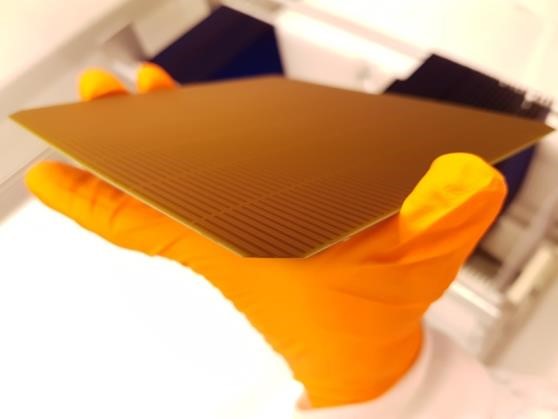

One of the main goals of WP7 in NextBase is the demonstration of 22% efficient back-contact modules with interconnection technologies and module materials with proven reliability and industry-relevance. To reach this goal we have been working on the development of next generation anti-reflective coatings, encapsulants and multi-wire based cell interconnection technologies.

This later element received a critical focus as the development of a cost-effective and efficient cell interconnection technology for back contact and heterojunction cells is key to accelerate the industrial uptake of back-contact cell and modules. We have explored two technologies. First technology aims to adapt the Smart Wire Connection Technology (SWCT) from two-side connected cells to back-contact cells. The second technology combines the soldering and encapsulation materials in one woven fabric. Both of these technologies are lead-free and use a low-temperature process. Next to the main goal of 22% module, we aimed to select interconnection design and materials to demonstrate a resistive loss of max 2 rel% and to meet 2xIEC standard requirements in damp heat and thermal cycling conditions and with a material of < 6 €cts/cell. A daunting challenge three years ago!

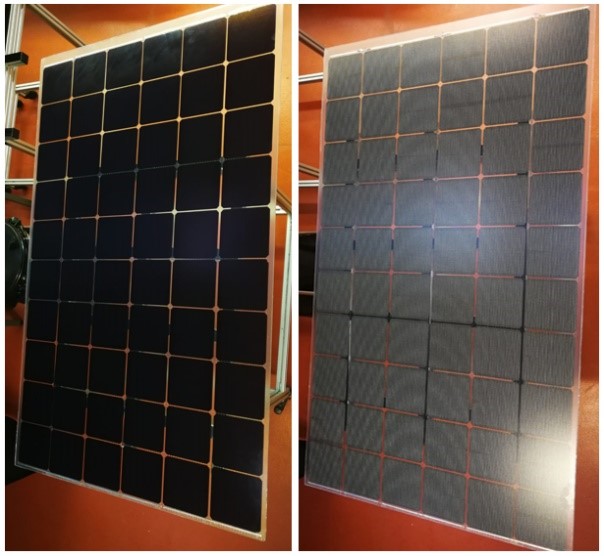

Expertise, innovation, hard work and very close collaboration between the cell and module teams enabled the NextBase project to report that nearly all objectives are achieved close the end of the project. In one cell laminates a record 23.2% efficiency on 90.2 cm2 active area has been achieved based on a 23.9% efficient cell using SWCT interconnection technology. Mini modules of 2×2 cells with a performance of 22% over 961 cm2 has been also achieved combining the SWCT and a new generation of anti-reflective coating. First proof-of-concept 60-cell module has been assembled with the SWCT technology. Using the combined solder and lamination approach the partners reported a functional 2×2 cell laminate Both interconnection technologies are particularly suited to make back-contact cells also bifacial. We estimate that as low as 3-3.5 €ct/cell interconnection material cost could be achieved, and currently the selected materials are undergoing extensive reliability testing (1x.5IEC requirement passed).

These results present a breakthrough for (heterojunction) back-contact cell technologies proving industry relevance of the multi-wire and low temperature (Pb-free) soldering interconnection technologies. As back-contact modules deliver the highest power/area they are particularly suited for integrated PV applications. We are confident that the technical building blocks developed in NextBase will be the foundation for novel module and PV applications. Overall nearly all ambitious objectives are completed few weeks before the project end! The secret sauce? One and only: a fantastic project team!